Comprehensive Guide on Selecting the Perfect Induction Heating Machine for Forging

In the realm of forging, precision and efficiency are paramount. The choice of induction heating machine plays a pivotal role in determining the quality, speed, and cost-effectiveness of your forging operations. With a myriad of options available in the market, selecting the right induction heating machine can be a daunting task. Fear not, as we present to you a comprehensive guide to help you make an informed decision.

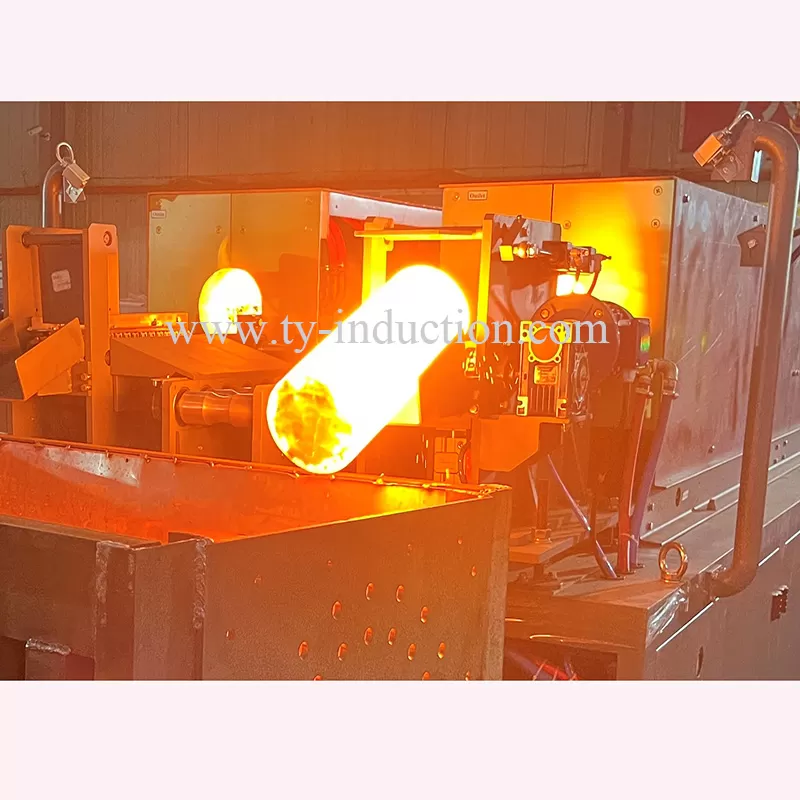

Before delving into the specifics of selecting an induction heating machine, let's first grasp the fundamentals of induction heating. Induction heating is a process where an electrical conductor generates heat when subjected to a fluctuating magnetic field. This phenomenon is harnessed in various industrial applications, including forging, due to its rapid heating capabilities and precise control over temperature distribution.

Key Considerations for Choosing an Induction Heating Machine

1. Heating Requirements

The first step in selecting the right induction heating machine is to assess your heating requirements. Consider factors such as the type and size of the material being forged, desired heating rate, and required temperature uniformity. Understanding these parameters will help narrow down the options and ensure that the chosen machine aligns with your specific needs.

2. Power Output

The power output of an induction heating equipment directly impacts its heating capacity and efficiency. Higher power outputs facilitate faster heating rates and are suitable for larger workpieces or materials with high conductivity. Evaluate your workload and choose a machine with an appropriate power rating to optimize performance and minimize heating time.

Recommended article:How to Melt Lead: A Step-by-Step Guide with Safety Tips

3. Frequency Range

What Factors Influence Hard Biscuit Production Line Purchases?

Solving Common Customer Concerns for Turnkey Solar Panel Production Lines

Resolving Common Issues in Cylindrical Lithium Pack Assembly Lines

What You Need to Know About 450 Kw Electric Generator

Revolutionizing Blade Lithium Battery Pack Assembly: Solving Your Efficiency and Reliability Woes

Unlocking Efficiency in Your Corn Mill Factory

Induction heating machines operate at different frequency ranges, each suited for specific applications. Low-frequency machines are ideal for heating larger and thicker materials, offering deeper penetration depths. Conversely, high-frequency machines excel in heating smaller and thinner materials with precision and control. Consider the size and type of your workpieces to determine the most suitable frequency range for your forging operations.

4. Control System

The control system of an induction heating machine dictates its operational flexibility and ease of use. Look for machines equipped with advanced control systems that offer precise temperature regulation, customizable heating profiles, and real-time monitoring capabilities. Investing in a machine with intuitive controls ensures efficient operation and enables seamless integration into your forging process.

5. Energy Efficiency

Efficiency is paramount in modern forging operations, and selecting an energy-efficient induction heating machine can significantly impact operating costs and environmental sustainability. Evaluate the energy consumption and efficiency ratings of potential machines, opting for models equipped with features such as power modulation, insulation optimization, and automatic shut-off to minimize wastage and maximize productivity.

6. Reliability and Durability

Reliability is non-negotiable when it comes to industrial equipment, and induction heating machines are no exception. Prioritize machines built with high-quality materials, robust construction, and proven reliability in demanding environments. Conduct thorough research, read customer reviews, and seek recommendations to ensure that the chosen machine can withstand the rigors of continuous operation and deliver consistent performance over its lifespan.

Conclusion

Selecting the perfect induction heating system for forging is a critical decision that requires careful consideration of various factors. By understanding your heating requirements, evaluating power output, frequency range, control system, energy efficiency, and reliability, you can confidently choose a machine that meets your operational needs and elevates your forging capabilities to new heights.

Recommended article:The Ultimate Guide to Choosing custom Flour Mills Machine

Essential Guide to Sieve Powder Equipment

What Are the Benefits of a Soft Biscuit Production Line?

How Can Automatic Scissors l-Bar Sealing Machines Enhance Your Packaging Efficiency?

7 Essential Tips for Using the SDM Belt Sander Effectively

How Will Innovation Shape Powder Grinding Machines?

Comments

0