What are SmCo magnets used for?

Introduction

Magnets play an indispensable role in our daily lives, from the refrigerator magnets that hold our shopping lists to the powerful magnets used in medical devices and industrial machinery. Among the diverse range of magnets available, SmCo (Samarium-Cobalt) magnets stand out as a unique and remarkable category due to their exceptional magnetic properties. In this article, we will explore the intriguing world of SmCo magnets, their composition, properties, and the wide array of applications they find in various industries.

Understanding SmCo Magnets

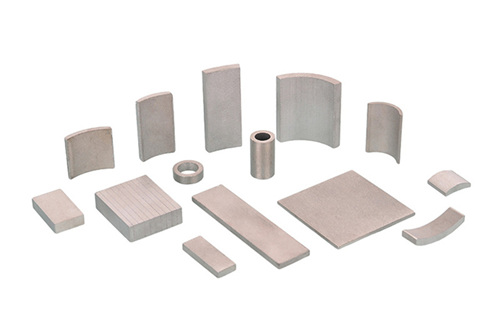

Samarium-Cobalt (SmCo) magnets are a type of rare earth magnet, known for their exceptional magnetic properties. They are composed of a combination of rare earth elements samarium and cobalt, along with traces of other elements. SmCo magnets are available in two main compositions: SmCo5 and Sm2Co17, with the latter being the most widely used due to its superior magnetic properties.

Composition of SmCo Magnets:

a. SmCo5: This type contains approximately 36-40% samarium (Sm), 12-14% cobalt (Co), and small amounts of iron, copper, and zirconium. These magnets are characterized by their moderate magnetic properties and relatively lower cost compared to Sm2Co17 magnets.

b. Sm2Co17: These magnets are the more popular and powerful of the two types. They contain approximately 25-32% samarium and 63-70% cobalt, with small amounts of iron, copper, and other elements. Sm2Co17 magnets offer higher magnetic energy and better performance in high-temperature environments.

Properties of SmCo Magnets

SmCo magnets exhibit several remarkable properties that make them unique and highly desirable in various applications:

High Magnetic Energy Product: SmCo magnets have a high magnetic energy product (BHmax), which allows them to generate strong magnetic fields, making them ideal for applications where strong magnetic forces are required.

High Temperature Stability: One of the standout features of SmCo magnets is their exceptional temperature stability. They can operate in high-temperature environments (up to 350°C) without significant loss of magnetic strength. This property makes them indispensable in industries where extreme heat is a concern.

Corrosion Resistance: SmCo magnets have excellent corrosion resistance, thanks to their composition. This property makes them suitable for applications in harsh environments, such as marine or aerospace industries.

Long Service Life: SmCo magnets are known for their long service life, which is crucial in applications where frequent replacements are impractical or costly.

Applications of SmCo Magnets

The remarkable properties of SmCo magnets open up a world of possibilities across various industries. Here are some notable applications where SmCo magnets play a crucial role:

Aerospace and Defense

SmCo magnets are widely used in the aerospace and defense industries due to their high-temperature stability and resistance to demagnetization. They find applications in:

Electric motors and generators for aircraft and missiles

Gyroscopes and compasses for navigation systems

Actuators and sensors in satellite systems

Magnetic couplings for submarines and naval vessels

Medical Equipment

The medical field benefits from SmCo magnets in various devices and equipment. They are used in:

Magnetic resonance imaging (MRI) machines to create strong, stable magnetic fields for imaging purposes.

Surgical instruments like magnetic forceps and catheters for minimally invasive procedures.

Dental equipment, such as handpieces and dental implants.

Drug delivery systems with precise magnetic actuation.

Industrial Applications

SmCo magnets have found a place in numerous industrial applications where their exceptional properties are harnessed for improved performance and durability. Some examples include:

Magnetic couplings and drive systems in chemical processing and petrochemical plants.

Magnetic separators for removing ferrous contaminants from materials in the mining and recycling industries.

High-temperature sensors and actuators in industrial automation.

Magnetic bearing systems for high-speed machinery, such as flywheel energy storage systems and air compressors.

Energy Sector

The energy sector has seen an increased use of SmCo magnets, particularly in renewable energy technologies. They are employed in:

Electric vehicle (EV) motors and generators for their high-temperature stability and energy efficiency.

Wind turbine generators to withstand the extreme conditions of wind farms.

Wave and tidal energy generation systems where corrosion resistance is crucial.

Magnetic levitation (maglev) trains for frictionless movement at high speeds.

Research and Development

SmCo magnets are essential tools in scientific research and development, providing a stable magnetic field for various experiments and equipment, including:

Particle accelerators used in fundamental research in physics and chemistry.

Nuclear magnetic resonance (NMR) spectrometers for studying molecular structures.

High-energy physics experiments requiring strong magnetic fields.

Magnetic resonance imaging (MRI) research and development.

Conclusion

Samarium-Cobalt (SmCo) magnets are a remarkable class of rare earth magnets known for their exceptional magnetic properties, high-temperature stability, and resistance to demagnetization. These properties make them invaluable in a wide range of applications across industries such as aerospace, medical equipment, industrial automation, renewable energy, and scientific research. As technology continues to advance, the demand for SmCo magnets is likely to grow, further highlighting their importance in modern society. Whether it's exploring the cosmos, improving healthcare, enhancing industrial processes, or advancing scientific knowledge, SmCo magnets continue to play a pivotal role in shaping our world.

Comments

0